Across industries that move the world’s most critical fluids. From oil and gas to chemical manufacturing and water treatment, precision flow measurement keeps operations efficient, sustainable, and safe. Among the technologies that make this possible, electromagnetic flowmeters (magmeters) stand out for their unmatched reliability and accuracy. They measure flow without obstruction, using electromagnetic fields to turn the movement of a fluid into precise, real-time data. But even the most proven technology faces limits when exposed to the complex chemistry of real-world process conditions.

For decades, Emerson has led the advancement of flow and process measurement, developing the industry’s most trusted magmeters under its Rosemount™ brand. Now, Emerson is turning outward, inviting engineers, scientists, and innovators to help solve the next challenge in this field: electrode coating buildup. Substances like paraffin, scale, and abrasive particulates can accumulate on electrodes, distorting flow readings and forcing operators into costly maintenance cycles and unexpected shutdowns.

The Electrode Code seeks innovative solutions that keep magmeter electrodes clean, accurate, and dependable for longer. Success means extending the meter’s effective lifespan, reducing cleaning frequency, and maintaining the precision that industries rely on, even in the harshest environments.

Winning solvers will share in a $30,000 prize pool and may earn the opportunity to collaborate directly with Emerson’s global R&D and manufacturing teams to bring their ideas from concept to commercial reality. By addressing this challenge, you’ll help shape the next generation of flow measurement , one that keeps industry moving without pause.

Background

Emerson

For more than 130 years, Emerson has been at the forefront of industrial innovation, advancing technologies that help manufacturers operate more safely, sustainably, and efficiently. From its beginnings in St. Louis, Missouri, as a pioneer in electrical engineering, Emerson has evolved into a global leader in automation and process control solutions. Within its Automation Solutions business, Emerson delivers one of the industry’s most comprehensive portfolios of flow measurement technologies, including Coriolis, vortex, differential pressure, and electromagnetic flowmeters. Each technology is designed to meet the demands of complex applications where precision and reliability are paramount. Emerson’s long-standing leadership in material science and sensor design enables its products to perform in environments that challenge conventional measurement tools.

Magmeters

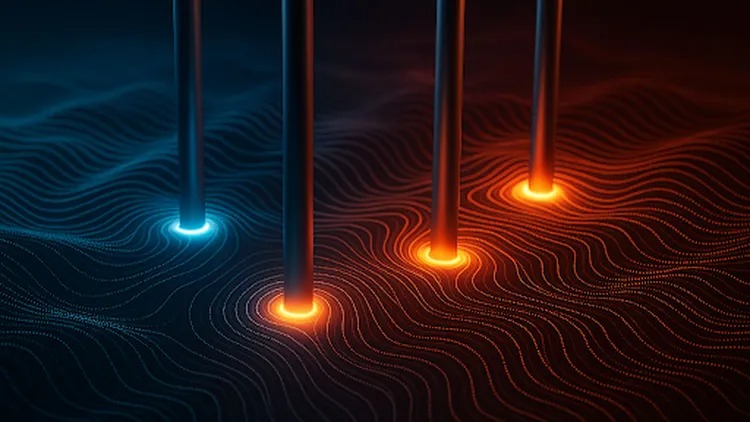

Flow measurement lies at the heart of industrial process control. All fluid that moves through a plant carries valuable information. Among the many flow technologies available, electromagnetic flowmeters (magmeters) stand out for their exceptional accuracy, reliability, and versatility. Operating on Faraday’s Law of Electromagnetic Induction, these meters measure the voltage induced as a conductive fluid passes through a magnetic field. That voltage, proportional to flow velocity, is then converted into a precise volumetric measurement by the transmitter. Because magmeters have no moving parts and introduce no obstructions in the pipe, they are widely used in industries handling aggressive chemicals, slurries, and abrasive or corrosive fluids, offering a durable, cost-effective solution even under harsh process conditions.

Over decades of innovation, Emerson’s magmeters have set the standard for flow measurement performance, operating general in a ±0.25–0.5% margin of error. Their robust sensor designs, specialized liners, and advanced digital signal processing minimize process noise and ensure accurate readings across a vast range of applications, from water management to chemical processing and oil production. Careful pairing of liner and electrode materials enables compatibility with diverse fluids and environments, protecting internal circuitry from corrosion and wear. These instruments are the trusted workhorses of flow measurement worldwide. Yet even the most advanced technology can encounter limits when operating in the toughest real-world conditions, such as when coating buildup forms on the electrodes, impeding their ability to measure flow accurately. Understanding and addressing that challenge is the next frontier in ensuring uninterrupted, precise, and maintenance-free flow measurement.

Measurement electrodes in electromagnetic flowmeters frequently become coated with substances such as paraffin and scale, causing significant malfunctions and accuracy issues.

When accurate fluid measurement is critical, and when interfering coatings are more likely to appear, these coatings create severe operational challenges. Coating buildup disrupts the electrodes’ ability to accurately measure fluid flow, leading to false readings, increased process noise, and in worst-case scenarios, complete meter failure. The economic implications are substantial; affected systems can require frequent, costly manual cleaning, causing downtime and process interruptions that may cost millions of dollars annually. Without a solution, operational efficiency suffers dramatically, and industries face continuous financial strain due to increased maintenance and potential shutdowns.

Electromagnetic flowmeter electrodes are vulnerable to fouling by various substances present in process fluids. The most common culprits are paraffin, scale (mineral deposits), and abrasive particulates such as silica sand, often the most prevalent solid in produced water. In oil and gas applications, paraffin is a waxy hydrocarbon that adheres readily to surfaces, forming a stubborn layer that is difficult to remove without damaging the electrode. In water distribution or industrial process streams, scale from dissolved minerals can accumulate over time, reducing performance. Compounding the challenge is the constant flow of abrasive solids (sand, heavy minerals, rust particles) that can quickly erode or wear away protective coatings. Previous coating attempts have failed because they dissolved or degraded under this continuous abrasion. In controlled testing, abrasive flow loops can simulate these conditions using known particle concentrations and material properties to assess wear resistance, a critical factor in designing a lasting solution.

Coating buildup interferes with the electrodes’ ability to accurately measure voltage induced by the moving fluid. As coatings grow, they cause process noise (voltage fluctuations from particulate impact or irregular surface contact) that mask the true signal. The result is a lower calculated flow rate and increasingly unstable readings. In advanced stages, the noise may become indistinguishable from the actual signal, making the meter unusable. Inaccurate measurements can have cascading effects: from incorrect billing in utilities to unsafe operating conditions in chemical and energy processes. Maintaining consistent, precise voltage readings is therefore as critical as preventing the coating itself.

The cost of adverse electrode coating is seen heavily in operational downtime, lost productivity, and repeated maintenance. In severe paraffin-laden environments, electrodes may require cleaning as frequently as daily, bringing operations to a halt. Scaling tends to accumulate more slowly, but can still cause problems over a 1+ year timeframe, depending on process conditions. Maintenance incurs labor costs, production stoppages, and the logistical complexity of handling equipment in hazardous or remote environments. Unplanned outages for cleaning or replacement can cost hundreds of thousands to millions of dollars annually, especially in industries where continuous operation is critical. The ideal solution would not only extend the time between interventions but also make cleaning faster, safer, and less costly when it is required.

Any viable solution must function reliably across the harsh environments where electromagnetic flowmeters operate. These can include temperature extremes from -20°C to 180°C (-4°F to 356°F), high-pressure systems, and fluids containing abrasive slurries or aggressive chemicals, including strong acids and bases. Even in the more common temperature range of 20°C to 80°C (68°F to 176°F), where most coating issues occur, solutions must endure fluctuating conditions without degradation. Abrasion from solids, chemical attack, and temperature cycling can each independently compromise a solution; together, they present a formidable test of durability. Designing for these conditions from the outset is essential to ensuring long-term field performance.

Develop an innovative solution that keeps electromagnetic flowmeter electrodes clean, accurate, and reliable over extended periods of operation, without the need for frequent maintenance or process interruptions. Your design may take the form of a coating, surface treatment, electrode redesign that effectively prevents buildup that interferes with measurement performance. The ultimate goal is to extend the effective life of the meter, ideally by a factor of two, before cleaning is required, while maintaining accuracy within the standard ±0.25–0.5% margin of error. Achieving this would not only reduce maintenance frequency but also minimize costly process shutdowns and lost production hours, delivering significant value to operators.

Successfully solving this challenge, you will submit a detailed proposal describing your concept, its materials and mechanisms, and evidence of its performance under realistic operating conditions. Submissions should demonstrate both technical feasibility and commercial potential. The following sections outline the must-have requirements a solution must meet to be eligible for review, and the desired features that will distinguish top-performing designs.

Must-have Requirements

Your solution, at a minimum, to be considered for a prize, must demonstrate:

- Conductivity: If submitting a coating solution, the material must be conductive, not dielectric, enabling accurate measurement even in low-flow or low-conductivity conditions.

- Environmental Compliance: Comply with REACH, RoHS, and similar regulations, explicitly avoiding PFAS or other “forever chemicals.” Solution should also not require the use of hazardous chemicals/materials in the manufacturing and preparation of the solution.

Desired Features:

The following, if met, can result in a higher score for your submission:

- Cost Efficiency: Demonstrate clear economic advantages, highlighting potential cost savings and commercial viability, with practical production and material sourcing.

- Wear Resistance Metrics: Provision of wear resistance data, such as representative particle sizes or Hardgrove index, for abrasive slurry conditions.

- Robustness: The solution must withstand harsh conditions, including high pressure, extreme temperatures (-20°C to 180°C), and abrasive slurries.

- Chemical Compatibility: Resistant to a broad range of chemicals, including strong acids and bases. The more chemicals with which the solution is compatible and effective, the higher the potential score.

- Compatibility: Solutions must be plug-and-play, compatible with existing electromagnetic flowmeters.

How do I Win?

To be eligible for an award, your proposal must, at minimum:

- Satisfy the Judging Criteria requirements.

- Thoughtfully address the Submission Form questions.

- Be scored higher than your competitors!

Awards:-

A total of $30,000 USD in prizes will be awarded to the top submissions that best meet the challenge objectives and judging criteria. While the cash prizes recognize the most promising ideas, this challenge is designed primarily as a gateway to partnership and development with Emerson, one of the world’s leaders in flow and process measurement technologies.

- Grand Prize: $20,000

- Two Runner-Up Prizes: $5,000 each

Beyond the cash awards, top solvers will be invited to collaborate directly with Emerson’s engineering and materials science teams to advance their proposed solution toward testing and potential commercialization. Selected innovators could gain:

- Access to Emerson’s extensive testing and validation facilities.

- Technical feedback and mentorship from industry experts.

- The opportunity to co-develop and scale a corrosion-resistant lining solution across Emerson’s global product portfolio.

By participating, solvers position themselves not only for recognition but for a potential long-term partnership, where their ideas can transition from concept to market-ready technology, improving reliability and sustainability across critical industries worldwide.

As a part of this challenge’s shared IP agreement, Emerson reserves the right to contact solvers regarding their submission, solution, and intellectual property. This may include questions about your solution and potentially partnership opportunities for further work, development, or testing with Emerson.

Deadline:- 05-02-2026